First Article Inspection (FAI), PPAP - Electronics manufacturing Services (EMS)

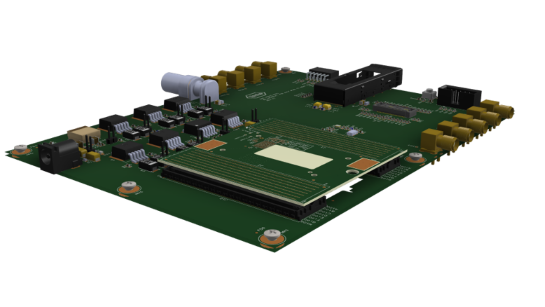

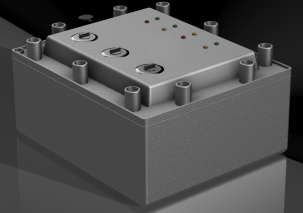

As a part of Electronics manufacturing Services (EMS) We perform ‘first article’ inspection, which is a complete and documented physical and functional inspection process. The purpose of a first article inspection is to provide evidence that all design and specification requirements are verified and recorded. The first article inspection process is a very important step in the manufacturing process of your printed circuit board assembly, wire harness assembly and box build assembly. When our PCB assembly line sets up your design, adhering to your defined specifications, the first circuit boards are generally considered ‘first article’ production. Ensuring that produced parts are in accordance with the design specification and customer expectations is crucial.Our first article inspection takes place before you begin serial production to ensure that products meet all requirements.

First Article Inspection - Benefits

- Provides validation that all documented requirements are met

- Helps establish the manufacturing Plan of Record (POR) for ongoing production. Once the POR is established, it must be replicated on an ongoing basis to ensure all future production meets documented requirements.

- Identifies potential problems during the first article build before on-going PCBA, Wire harness and Box build production. Corrective actions for any problems can then be implemented prior to full production.

Why choose Argus for FAI ?

- Ensure parts are produced in accordance with the design data and specification.

- Make informed decisions between design and production, so you can factor in any required improvements before beginning production.

- Establish a platform to discuss your expectations and any other improvements and requirements.

- Avoid risks during production and failures due to the immaturity of processes.

- Deliver an agreed product to the customer and gather the input for the process evaluation (the last article inspection).

Trusted FAI from a leading EMS Provider

As a leading inspection provider, we offer you unrivaled experience and expertise in providing first article inspection for PCB Assemblies, Wire harness Assembly and Box Build Assembly. With our global reach, we can provide first article inspectors with our experienced team for customer and OEM requirements.

Our first article inspection service includes:

- Planning and scheduling of the first article inspection in close communication with the product supplier, OEM and customer.

- Performing the first article inspection.

- Reporting

First Article Inspection Steps

- Measured Attributes– dimensions, voltages, resistance, or any other measurable attributes are measured, recorded and verified against the covering design specification.

- Manufacturing Issues – any difficulties, problems, or concerns during the PCBA process are examined for changes and corrections.

- Source Validation – all parts and materials used are verified to match their specifications.

- Documentation Verification – to identify and clarify any documentation confusion.

Argus Systems (AESPL) is a globally recognized Product Engineering and Electronic contract Manufacturing company providing electronic product design, product Reverse Engineering, Product Re-engineering, Hardware reverse engineering, Software reverse Engineering, Printed Circuit Board Reverse Engineering, value engineering, Product Life-cycle Management services.

Electronics Manufacturing Services (EMS) Includes PCB Fabrication, PCB Assembly, wire Harness & cable Assemblies, Conformal Coating, Electronic Potting, PCBA Stencil fabrication, Box Build assembly, Test fixture, System-Level Assembly, Regulatory compliance Testing and Electronic manufacturing supply chain solutions for Its Global Clients in India, USA, UK, Germany, France, UAE, Saudi Arabia, and Australia.