Electronic System and PCB design, analysis and consulting

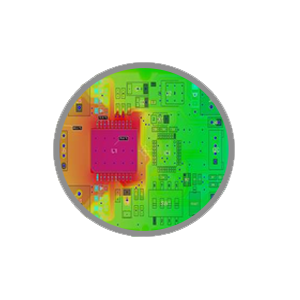

Signal Integrity Analysis, Power Integrity Analysis, Thermal Analysis, Reliability Analysis, EMI EMC Analysis, DFM, DFA, DFT

Signal Integrity Analysis, Power Integrity Analysis, Thermal Analysis, Reliability Analysis, EMI EMC Analysis, DFM, DFA, DFT

Argus is a leading provider of PCB design and system-level design and analysis services, specializing in

Signal Integrity (SI) analysis, Power Integrity (PI) analysis, Thermal analysis,

Crosstalk analysis, EMI/EMC analysis, and Reliability, Availability, and Maintainability (RAM) analysis.

Our expertise extends to end-to-end PCB layout design and validation for high-reliability applications across multiple domains including

Space and Avionics, Telecom, Industrial,

Medical Electronics, Computing, and

Automotive Systems.

With increasing design complexity, many companies face critical challenges related to PCB signal integrity, power integrity,

thermal performance, electromagnetic interference (EMI), and overall system reliability.

These issues often lead to project delays, compliance failures, and rising development costs.

Organizations without in-house analysis capabilities—or those encountering peak workload demands—can benefit from outsourcing.

Argus offers quick-turn PCB and system-level design analysis services, providing expert engineering resources to help reduce design risks,

accelerate timelines, and lower costs through efficient and accurate simulation and validation workflows.

Pre-Route and post-route PCB Si Analysis

Library and model Development

Pre Layout PCB SI Analysis Check

Post Layout PCB SI analysis check

DC Drop Analysis

Decoupling Analysis

DC Noise Analysis

RF Simulation Process considers below aspects of PCB Design & PCB layout design:

Signal Integrity analysis, Power Integrity Analysis (PI analysis), Thermal Analysis, EMI EMC Analysis, Reliability Analysis, DFx Analysis

Argus Systems a globally recognized Electronic Hardware Design and electronic manufacturing company Providing hardware system design, Electronics Hardware design, PCB layout design and electronis product design analysis (PCB Signal Integrity analysis, PCB Power Integrity analysis( PI analysis), PCB crosstalk analysis, Derating analysis, PCB Thermal analysis, PCB Reliability analysis, PCB EMI EMC analysis, derating analysis PCB DFM analysis, PCB DFA analysis, PCB DFT analysis) to Its Global Clients in India, USA, UK, Germany, France, and Australia for Automotive, Medical, Aerospace & Defense and Industrial applications.