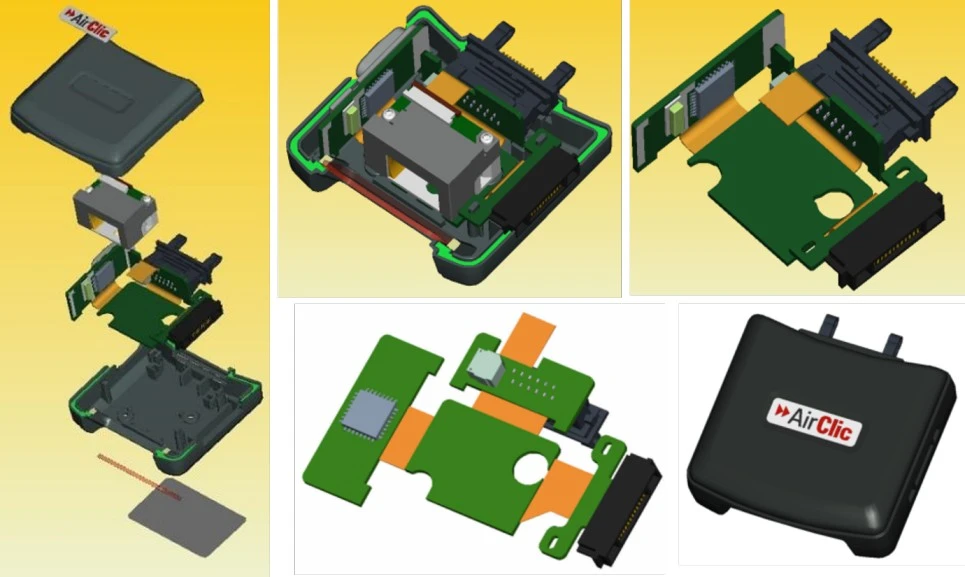

Mechanical fabrication - Plastic and Metal Parts

- Argus Mechanical Design and Manufacturing solutions leverage our vertical design & manufacturing model and capabilities under one roof in a cost-effective manner.

- Entire lifecycle support of a product from mechanical design targeting DFM efficiency to prototyping, to cost-effective high-volume production.

- Plastic enclosure design for various electronic products, considering molding feasibility in the design stage itself, which reduces production time and cost.

- For plastic parts We use snap fits, interlocking joints, threaded fasteners, glue for connections based on application and customer requirements.

- Suggestion for suitable material, material thickness, product shape and structure based on the application and usage of the product.

- Rapid prototyped SLA & SLS plastic parts and enclosures with materials like ABS, PP and PLA.

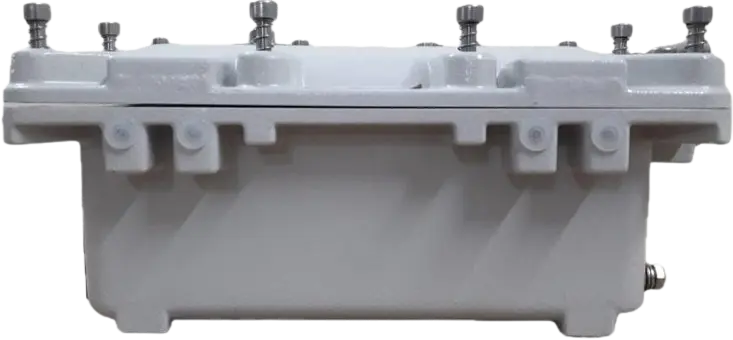

- Injection Moulded IP5x & IP6x Plastic Parts & enclosure.

High-precision plastic and metal parts manufacturing

- Manufacturing of Injection Moulds and Compression Moulds to support a variety of Materials such as PP, LDPE, HPDE, Nylon 6, ABS, PC, Clear PC, PMMA, TPE & SAN.

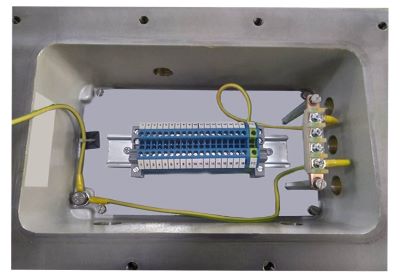

- Custom sheet metal enclosure manufacturing solutions in aluminium, mild steel and stainless steel with sheet thickness 0.5 mm to 10 mm.

- The Sheetmetal's are processed by CNC laser/profile cutting and CNC bent after which powder coating or anodizing is done as per product preference.

- Sheet Metal Fabrication Machines includes Hydraulic Presses, Spot Welding, Arc Welding, Sheet Rolling, Precision Bending, Pipe Bending, Laser Cutting & Engraving.

- CE, ATEX & IECEx approved Aluminium enclosures and stainless steel enclosures.

- With 20+ experience in them OEM/ODM industry, our expertise is high precision plastics and metal parts made to spec.

- Our primary application includes Automotive, Oil & Gas, Aerospace & Defence.

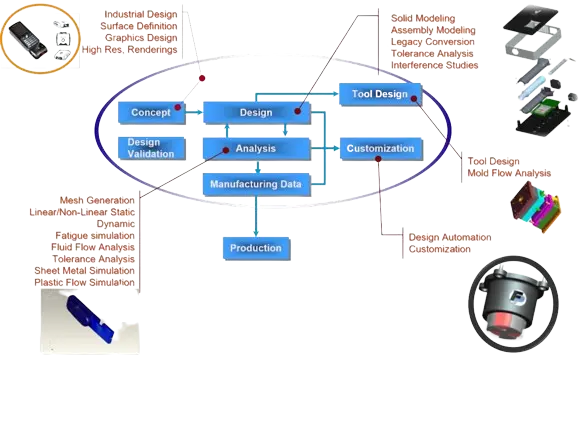

Ideation & Market Research

Ideation & Market Research

- Based on the customer requirement and application of the product which is intended to develop, we will do Market Research and based on it we will work on Ideation, so we don’t have any IP conflict.

- The success of any product depends on its Human Interface and User Analysis which is our key expertise while ideating any concept.

- Based on the above-mentioned points, we will come up with 4-5 Concept sketches which will show different form factors.

Industrial Design / CAD Design

- Upon confirmation of the detailed sketches, the detailed 3D modeling will be done.

- Manufacturability, Aesthetics and Proper Fitment of internal components will be done with utmost care.

- In the design stage itself, we will suggest the Tooling Cost on different design options.

- Once the design is ready, we will carry out Thermal Analysis/Vibration Analysis on customer demand.

- Creating Manufacturing Drawings and Necessary Documents to build Prototype.

Industrial Design / CAD Design

Prototyping

Prototyping

- Prototyping is done using various techniques like 3D Printing (FDM, SLS, MJF, SLA, MJP), CNC Machining, Sheet Metal Laser Cutting and CNC Bending.

- With the Printed parts, Checking the fitment of internal components and ensuring the working of the device with everything assembled.

- The Printing can be carried out multiple times with minor tweaks until ensuring all the aspects of the requirement are fulfilled.

Low Volume Production & Certification

- Low Volume Production for plastics using Vacuum Casting and Silicone Molding.

- CNC machining for plastic Enclosures and Aluminum Enclosures which have Low Volume Production requirement.

- Laser Cutting, CNC Bending and Powder Coating/Anodizing methods in case the part is made of Sheet Metal Enclosures.

Low Volume Production & Certification

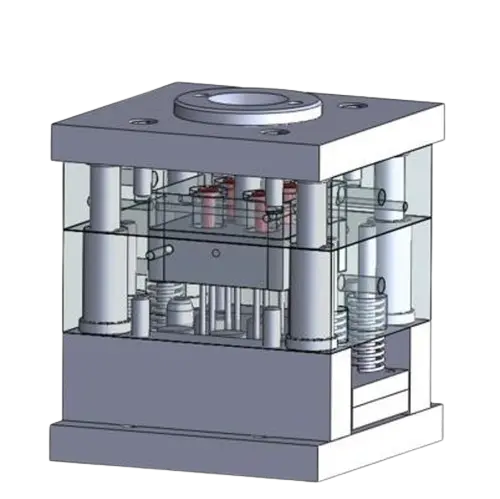

Tooling and Manufacturing

Tooling and Manufacturing

- In-House Tool Room Facility allows us to take care of creating Injection Moulds.

- The Injection Molds Designs are done to ensure the tool design is manufactured in the most cost-effective way, while maintaining the highest Quality.

- Tool Makers can handle Injection Molding Tools involving, Double Shot Molds and highly complex molds involving many Lifters.

- Can create Multi Cavity Molds as per Production Demands.

Aluminium Die-Casting

- Aluminium Die-casting designing & manufacturing.

- Pressure Die Castings.

- Material: Aluminium.

- Finishing: Powder coating or liquid painting.

- Processing: Machining, heat treatment and sand blasting etc.

- Casting types: No-Bake, Dry Sand, Semi-Permanent Mold,Permanent Mold.

Aluminium Die-Casting