System level & PCB PI Simulation and analysis

PCB Power Integrity is not a new term in high-speed digital design and analysis. Ever increasing count of PCB layout planes, form factor limitation, high IC density, cost constraint are few of many factors which results in complex electronic designs. Power integrity Analysis ( PI Analysis ) is sometimes assumed as a sub discipline of Signal Integrity, but as they are coherently related they have distinctive features of their own which are to be done in different ways. Signal Integrity analysis is based on transmission lines whereas in Power Integrity analysis we are dealing with power distribution through transmission planes.

Electronics System & PCB Power Integrity Analysis

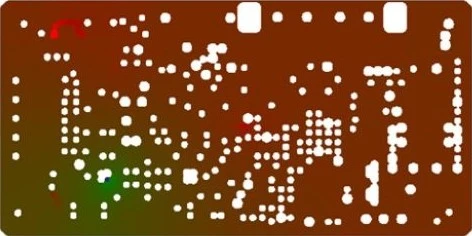

PCB Power Integrity Analysis ( PI Analysis) can identify the potential problems and with appropriate modifications and validations the analysis can be done again, this trial and error approach helps to identify problem on virtual prototypes and saves in turn cost of actual manufacturing and later re-spin of boards.

- A power delivery network (PDN) has to deliver sufficiently clean power supply to ICs.

- The PDN has to provide low noise reference path to signals.

- The PDN should not radiate excessively.

Power Integrity Analysis Types

Each of these phase requires expensive tools and capital equipment expenditures which can be lowered significantly if these can be outsourced to the external custom electronic design team that has the required tools and experience. This will in turn reduce the operational cost of the start-up business and help them to focus on their strategy and lean them to profitability.

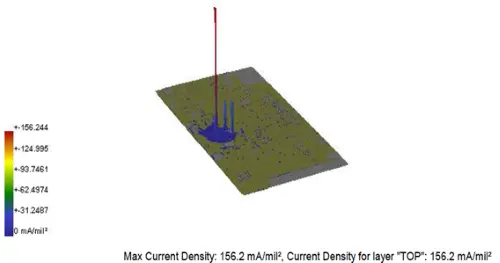

- DC Power Integrity ( IR-Drop analysis) : Analysis of trace and plane shapes to determine how much voltage is lost due to the resistance of copper.

- Decoupling analysis : To meet low impedance requirements.

- Noise analysis : Noise analysis of IC Power pins or from via to another.

- For high-speed and highly-reliable PCB design it is essential to perform pre-layout PDN analysis and Power Integrity analysis is a must for it.