Signal Integrity, Power Integrity, Thermal, EMI, EMC, Reliability, DFM, DFA, DFT

Argus is a leading provider of PCB design and system-level design and analysis services, specializing in

Signal Integrity (SI) analysis, Power Integrity (PI) analysis, Thermal analysis,

Crosstalk analysis, EMI/EMC analysis, and Reliability, Availability, and Maintainability (RAM) analysis.

Our expertise extends to end-to-end PCB layout design and validation for high-reliability applications across multiple domains including

Space and Avionics, Telecom, Industrial,

Medical Electronics, Computing, and

Automotive Systems.

With increasing design complexity, many companies face critical challenges related to PCB signal integrity, power integrity,

thermal performance, electromagnetic interference (EMI), and overall system reliability.

These issues often lead to project delays, compliance failures, and rising development costs.

Organizations without in-house analysis capabilities—or those encountering peak workload demands—can benefit from outsourcing.

Argus offers quick-turn PCB and system-level design analysis services, providing expert engineering resources to help reduce design risks,

accelerate timelines, and lower costs through efficient and accurate simulation and validation workflows.

Signal Integrity Analysis

Pre-Route and post-route PCB Si Analysis

- Reflection Waveform Analysis

- Crosstalk Analysis

- Propagation delay and timing analysis

- Eye Diagram Analysis

- IBIS Model Creation

- IBIS Model validation

Library and model Development

Pre Layout PCB SI Analysis Check

- Placement optimization, Trace length constraints

- Impedance requirement.

- Topology and termination strategies.

Post Layout PCB SI analysis check

- Verification by extraction of actual PWD parasitic.

- Placement optimization based on signal flow & trace length requirement of the specific interface.

- Layer stack-up recommendation.

- Reflections analysis and determination of termination scheme.

- Generation of PCB layout constraints & guidelines.

- Delay & Timing determination.

- Crosstalk level estimation.

- Eye diagram analysis.

Power Integrity Analysis

- Power Integrity can identify the potential problems and with appropriate modifications, validations it can identify problem on virtual prototypes.

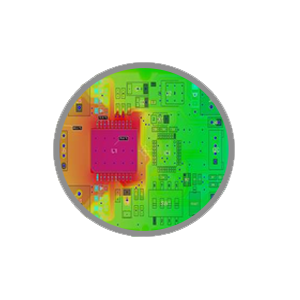

DC Drop Analysis

- Modeling Power Plane structures to validate IR/DC drop in power supply

- rails due to copper losses.

- Output available in the form of a report indicating current flow and voltage at each power pins of circuit devices.

- 3D Plots generation representing voltage distribution through the power planes.

- Current density 3D plot.

Decoupling Analysis

- Analyzing the impedance of the power distribution network at multiple board locations and suggesting proper decoupling schemes.

- PCB layout Stack up suggestions for proper board decoupling.

- Frequency versus Impedance plot.

DC Noise Analysis

- Simulation of plane noise due to improper decoupling schemes.

- A 3D plot of plane noise.

System, PCBA, PCB Thermal analysis

- System and PCB Thermal Analysis, simulation, and Design.

- PCB data import through IDF files available from all EDA tools.

- Component Junction and case temperature computations.

- PCB Thermal profiles generation for components and PCB.

- Reports consist of board temperature and gradients, excess temperature, 3D airflow, and temperature distribution.

- Simulation of Metal Core Designs and verification of the cooling effects and application design modifications.

- Detection of hot spots and correction with heat transfer mechanisms analysis viz., Conduction, Convection, Radiation.

- Support on Heat Sink Design and cooling proposals.

- System and PCB Thermal analysis of applications like Defense, Avionics, Telecom, Medical, Computer, Automotive, and Power supplies.

Electronics Hardware reliability analysis

- System and PCB Reliability Analysis.

- System availability analysis.

- System maintainability analysis.

- System and PCBA Failure mode, effects, and criticality analysis (FMECA )as per MIL-STD-1629A.

- Uses Reliability diagram, Fault tree analysis, and applicable standard models.

- Failure rates and MTBF Analysis based on MIL-217 models.

- Reliability prediction as per Telcordia/ Bell core (TR-332/SR-332) models.

- Reliability Prediction as per IEC62380 models.

- Reliability Analysis consists of MTBF calculation for all components present in the card.

- MTBF vs Temperature range graph.

- Derating analysis.

- Reliability Reports with details of Failure rate by part type and Failure rate parts list.

- System and PCB Reliability Analysis for Defence and Aerospace Applications includes Airborne, Commercial, Naval, Missile, Ground Fixed and Ground Mobile.

EMI EMC simulation & analysis

- Printed circuit board Level and System level analysis.

- Radiated Emissions Analysis.

- Near Filed, Far Filed Emissions

- Net and Board level radiated emissions

- validation as per Compliance template of FCC, CISPR, VCCI, User

- Support and guidelines for selecting the appropriate filters for various applications.

- EMC Control Planning.

- EMI Test Plans and Procedures Development.

- EMI EMC Product design review.

- EMC Performance Requirements Definition.

- Design mitigation.

- Gap Analysis & Risk Mitigation Plans.

- Compliance risk assessments.

- Flow Down Requirements.

RF Simulation & Analysis

-

RF Simulation Process considers below aspects of PCB Design & PCB layout design:

- Material Selection

- Control of Impedance

- Trace Design

- Earth Plane, Ground Plane

- Shielding

- Via Management

- Component Placement

- Power Supply Decoupling

- RF Circuit Simulation

- Electronic (EM) Simulation

- RF System Simulation

- RF Antenna optimisation

- RF system Thermal Simulation

- RF system mechanical Simulation

DFX ( DFM, DFA, DFT) analysis

- Design for manufacturing (DFM) analysis.

- Design for assembly (DFA) analysis and evaluation.

- Design for Test (DFT) analysis as per specific test fixture requirements.

- Verification of inputs files for CAM Compatibility, generating reports on individual board characteristics against manufacturing spec.

- Verification of opens and shorts, Matching of drill data for accuracy.

- Layer Analysis for annular ring, space & trace widths, solder Mask, fiduciary openings & exposed traces.

- Silkscreen removal, scoring, V-cuts, routing, slot, route and retain, test coupons

Manufacturing Feasibility analysis, CAM

- Manufacturer’s requirement for volume manufacturing is very important aspects that need to be identified before design & building the prototypes.

- Using sketch data of PCB, PCA analyze product potential for manufacturing success.

- Manufacturing SWOT Analysis

- NPI & PPAP Process Mapping

- Compliance & Legal Assistance

- Cost/Profit /Risk Analysis

- First article inspection services ( FAI ) to ensure that produced parts are in accordance with the design data, the specification and customer expectations.

Argus Systems a globally recognized Electronic Hardware Design and electronic manufacturing company Providing hardware system design, Electronics Hardware design, PCB layout design and electronis product design analysis (PCB Signal Integrity analysis, PCB Power Integrity analysis( PI analysis), PCB crosstalk analysis, Derating analysis, PCB Thermal analysis, PCB Reliability analysis, PCB EMI EMC analysis, derating analysis PCB DFM analysis, PCB DFA analysis, PCB DFT analysis) to Its Global Clients in India, USA, UK, Germany, France, UAE, Saudi Arabia, and Australia for Automotive, Medical, Aerospace & Defense and Industrial applications.